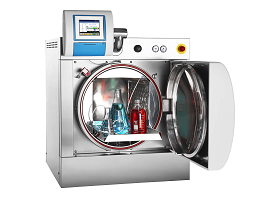

FOB – Benchtop Lab Sterilizer

High-performance and modular design.

FOB is a bench top lab steriliser that combines excellent performance with high quality materials, ease of use and reduced utilities consumption.

The FOB series are suitable for many different applications, making it the perfect choice to satisfy modern laboratory needs. FOB series autoclaves combine technology and know-how, and can be used by very different laboratories, such as:

- Private and public microbiology labs

- High schools and universities

- Research institutes, life sciences and biotech labs

- Clinical diagnostic labs

- Agriculture, environmental and veterinary labs

- Material testing laboratories

- Quality control lab´s in pharma, food/beverage, chemistry/cosmetics and other industrial sectors.

FOB series autoclaves are used in highly specialized fields thanks to a wide selection of options on a modular system. Hence, FOB sterilizers can be configured to meet the most demanding user´s requirements.

FOB may be adapted to satisfy various laboratory applications and the treatment of many different types of loads, including waste with high pathogen risk, in addition to solid porous goods, packaged items and liquid/media, in open and sealed containers.

FOB has a modular design, to meet the widest possible range of our customers’ needs.

Design and Technical Features

FOB series of bench top lab sterilizers can be designed with four different chamber dimensions with single or double hinged doors for pass-through applications:

- FOB2-TS: 47 liters, single hinged door

- FOB2S-TS: 75 liters, double hinged door

- FOB3-TS: 90 liters, single hinged door

- FOB3S-TS: 122 liters, double hinged door

A unique opening/closing door system, with patented pneumatic gasket seal, guarantees it's perfectly airtight, provides maximum reliability and has improved safety for operators. Moreover, FOB autoclaves can be equipped with safety device in compliance with TRB402 and a thermal interlock to prevent the door from opening.

Chambers, pneumatic valves and hydraulic components are made of 316L stainless steel, with a sanitary electropolished finishing. FOB is designed to assure wide and easy access to the technical area for maintenance activities.

Easy installation and quick connection to the utilities makes the FOB series autoclave even more attractive. To ensure energy savings, FOB has a heat exchanger recovery system installed outside of the chamber to reuse the heat of the condensate for water pre-heating before the steam generation.

FOB series is equipped with DCS PLUS 10 process controller: 30 cycles, easily customizable in a multi-user environment, with a large touch-screen color display and interface for remote monitoring via Ethernet control. The DCS PLUS 10 process controller is fully validated and documented.